Description

Features:

- Support current through: maximum 3.000A resolution 0.001A

- Maximum voltage measurement error: 1% + 0.02V

- Maximum current measurement error: 1.2%+-0.002A

- The highest battery capacity range: 9999Ah (1Ah=1000mAh). The larger value is switched by the decimal point shift. When it is lower than 10Ah, it is displayed as X.XXX, and when it is above 10Ah, it is displayed as XX.XX, and so on.

- Board size: 50mmX37mm

- Finished product size: 50mmX37mmX17mm (length X width X height maximum position size, including copper foot height)

- Board and accessories weight: single-board 28g (including copper column), two 5W ceramic resistors 9g, 50W resistance about 27g (including line)

Note:

In order to improve the voltage measurement accuracy, this circuit specially designed the DC offset. When the terminal is not connected, it will display a small voltage, which does not affect the actual measurement. If you short-circuit the input terminal (absolute 0V), it will display 0 If you want to understand the principle, you can check the superposition theorem in electrical engineering.

During the use of resistance discharge, the resistance load will be severely heated, please pay attention to safety! 50W aluminum shell resistor (has been welded a high-temperature wire), please install it on the metal plate!

Instructions:

1. The battery under test should be fully charged first.

2. Connect the positive pole of the battery under test to the positive input, the negative pole to the input negative pole, and the reverse polarity (the reverse connection with the load may damage the circuit)! Connect the load to the output positive and output negative, and give the tester micro USB working power (not available for desktop or notebook USB), and the battery voltage is displayed.

3. To start the test directly, just press the “OK” button, the tester can automatically set the appropriate termination voltage according to the battery full charge voltage and will flash the display 3 times to start the test. Need to manually set the termination voltage only need to press the “+” or “-” button to modify the battery voltage display state, the termination voltage display is P beginning, the latter represents the voltage value, the resolution is 0.1V, after setting, press “OK” “start testing.

4. After the test starts, the tester will turn on the electronic switch that controls the load. The test process data display will be displayed between the discharge capacity (Ah), the current discharge current (A) and the battery voltage (V). When the battery voltage reaches the set termination voltage, the tester cuts off the load control switch, and the display data stays on the capacity (Ah) and flashes rapidly with the corresponding indicator light. The capacity displayed at this time is the actual discharge capacity of the battery. “OK” can terminate the flashing to make the data display stably. Press the “OK” button again to return to the power-on state and replace the battery test.

Error code and meaning:

Err1: Battery voltage is higher than 15V

Err2: Battery voltage is lower than the set termination voltage

Err3: The battery cannot withstand the load discharge current or the line internal resistance is too large

Err4: The current is too large (current exceeds 3.1A)

Err5: Improper use or wiring error has caused the device to burn out and cannot be used (current sampling or control switch MOS burned)

Secondary calibration operation (after self-running calibration, it means to give up the warranty):

Press and hold the three buttons at the same time to power on the tester, enter the calibration mode, first display the number of calibration records and then enter the official calibration sampling program display 0u0A, then short-circuit the input positive and negative, then press the “OK” button to complete the display J10u, Apply 10.00V standard DC voltage between the input positive and negative poles, then press the “OK” button, then display J2.0A, apply 2.0A constant DC current to the output negative pole (inflow direction) and input negative pole (outflow direction) and press Move the “OK” button to complete the calibration. The tester pre-audits the calibration data. If the calibration data is reliable, it will display 4 calibration numbers and then exit. If the pre-audit considers the data to be unreliable, the data will be discarded.

Package Includes:

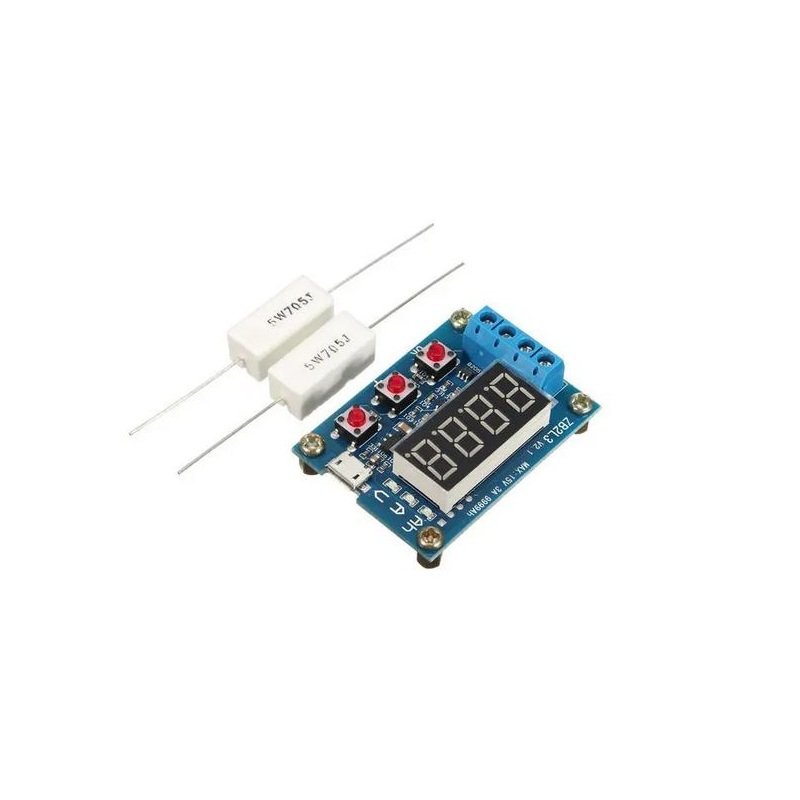

1 x ZB2L3 Battery Capacity Tester.

2 x Resistor.

Reviews

There are no reviews yet.